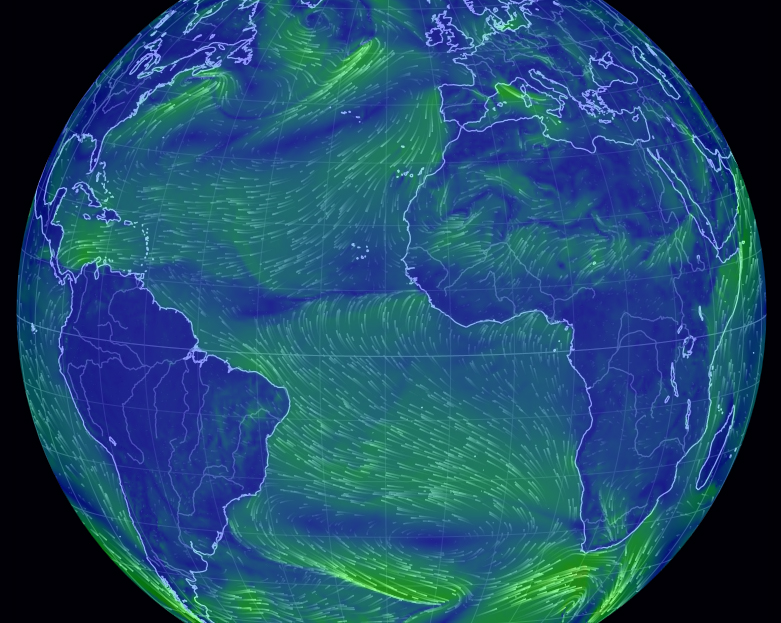

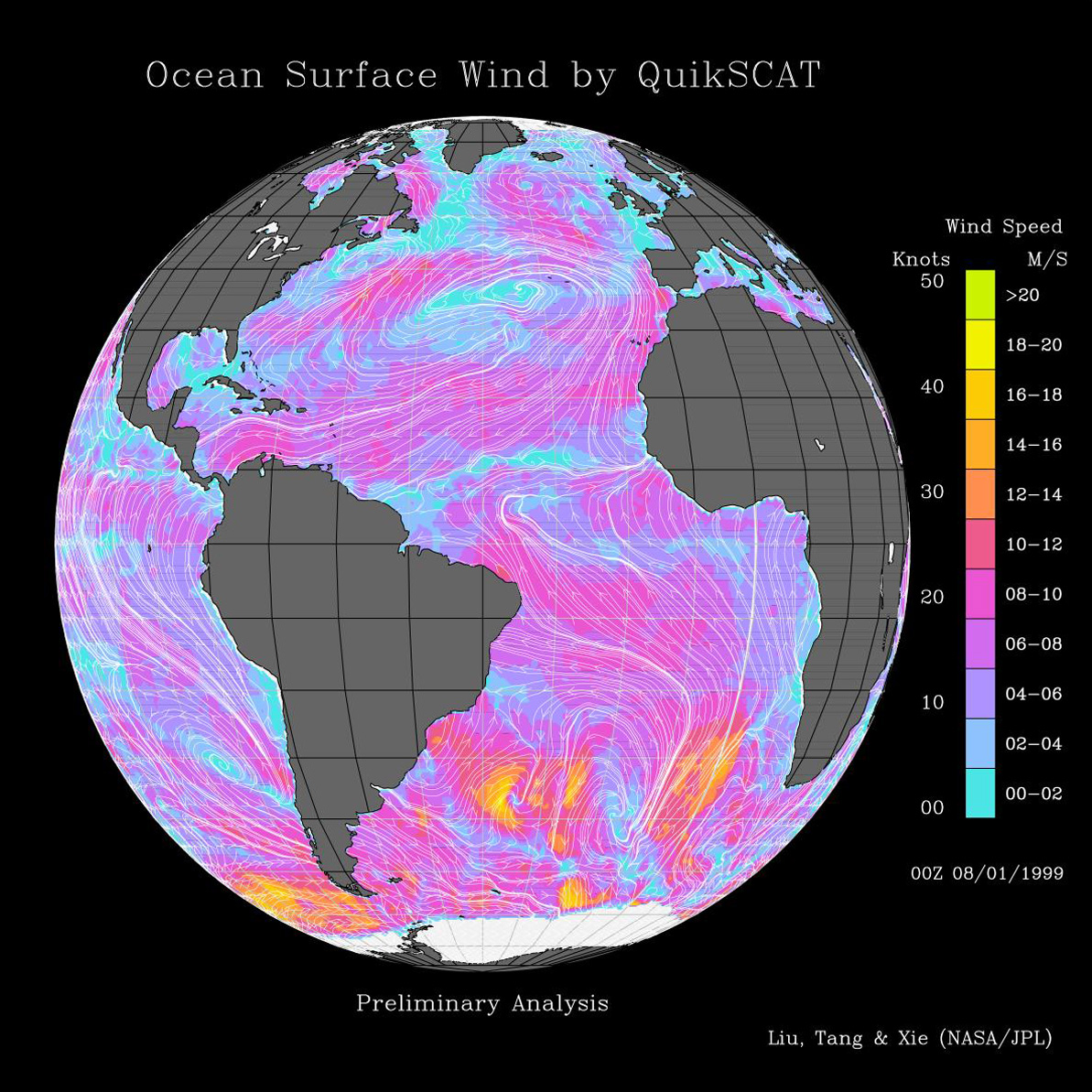

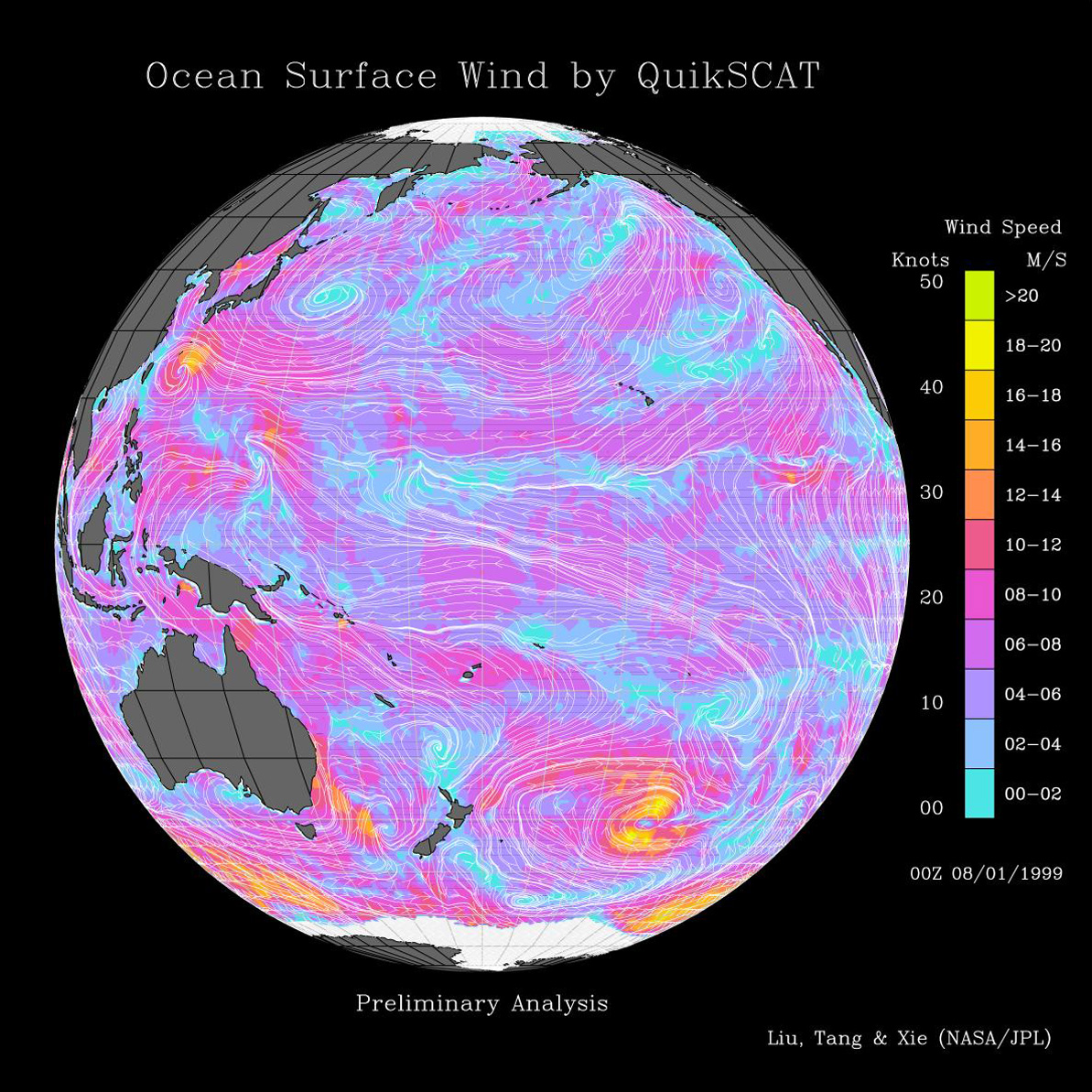

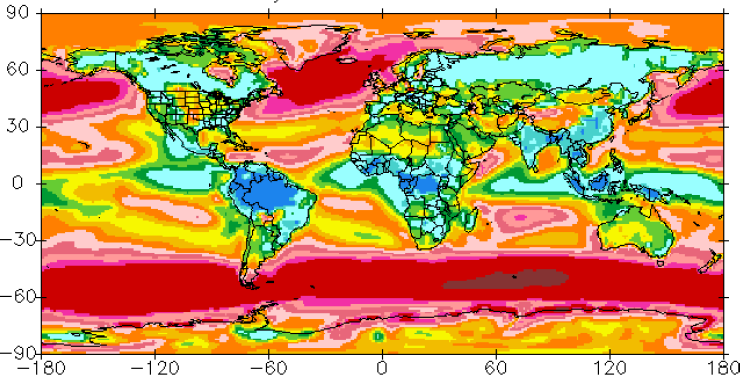

The most stable wind systems on earth are the trade wind zones. One can clearly see these in the above graphics, north and south of the equator, in form of the southeast trade wind and the northeast trade wind. These wind zones move with the seasons, and during winter their winds are stronger than during summer. The KITE GAS/FUEL SHIP power plants move with the seasons, too, and navigate AI-supported according to the wind forecast to operate with a maximum capacity factor or 80-90% per year, resembling an operation time with full load hours of 7000-7800 hours per annum.

Energy Ships harvest Wind Energy on the open Ocean

OCEANERGY develops the K1 Kite Propulsion system since 2012 in Stuttgart, the hub of finest German engineering, and at its Kite Test Center in Cape Town (South Africa) with excellent wind and test opportunities, at the “Cape of Storms”.

The underlying Energy Ship technology OCEANERGY develops with its partners

from the areas ship construction and ship building,

and from electrolysis and hydrogen technologies.

In the area of power production from the traction of kites, the complex topic traction-to-power, OCEANERGY applies entirely new and unique technologies. In particular the patented Traction-to-Power Method II is the basis for competitive advantage. It implements Kite Cycle Pumping technologies on a ship. First, the K1 Kite Propulsion system produces electricity, directly, with one or more Kites. Then the about 50% considerable residual traction force is used for ship propulsion. Stationary AWE systems or wind turbines waste this residual force and it is lost (actually induced into the earth). Method II has therefore a very high overall efficiency.

The unique RES Kites, made out of composite textiles, developed by OCEANERGY, inspired by space technology and patented, have an extremely low weight and therefore excellent low-end wind capabilities. These fly in 6-8kn and problems with the Kite are therefore minimized already by design. The operating capabilities of such a mast-less AWE system are maximized, the Kite can be kept up in the air at all times. Mast-less systems have the supreme advantage that they can be scaled much easier to highest power [MW], than mast-based systems, such as turbines or sails. These RES Kites can handle highest loads, up to 5 000 N per m2.

OCEANERGY’s proprietary and highly innovative Launch-Land-System LLS enables maximum scaling and kite sizes, and power [MW] of the K1 Kite Propulsion systems. It allows scaling far beyond what wind energy experts have thought to be possible. It will lead to commercial breakthrough of AWE technologies. Inquiries by Investors and Customers welcome.

The Energy chain destined for 55MW (2029) and beyond 100MW (2035)

The functional energy chain of the unique K1 Kite Propulsion system, and its results:

- LLS Launch-Land-System (e.g. PCT ZA2021/061961): resulting in many m2 Kite.

- RES composite Kites (e.g. EU 21839807.1 or US 18-031,019): resulting in highest traction loads [N and MW.mech] and extreme low-end (light wind capabilities).

- Traction-to-power Method II (e.g. EU 20817493.8 or US 17-776.076): resulting in very high efficiency for conversion traction-to-power [MW.el]. Harvesting the residual force allows for navigating the Energy Ship, and SMART NAVIGATION according to wind forecast increases significant power output further.

OCEANERGY’s Energy Ships implement the physics concept of “Airborne Kites on a Moving Platform”. See e.g. recording webinar no. 5 on www.hydrogen-universe.com. This principle is far superior to stationary/fixed AWE systems, and therefore of course also to wind turbines: By movement of the the ship the RES Kites harvest apparent wind, which can be considerably stronger than true wind. Depending on the type of watercraft this increase can be 1,5x – 2x more power. In special applications even 4x – 8x more power.

In comparison to (stationary/fixed) wind turbines Energy Ships can achieve 32x more energy (!) per year and square meter.

OCEANERGY’s technology is geared to harvest wind energy, where the wind is strongest and permanent:

On the open ocean, in permanent wind zones.

Near endless space and scalable beyond any practical limits.

In no-man’s land.

Energy Ships: mobile Wind Power Plants on the open Ocean

Offshore wind turbines, regardless whether on a fixed base in shallow waters, or floating on a swimming foundation are passively waiting for wind.

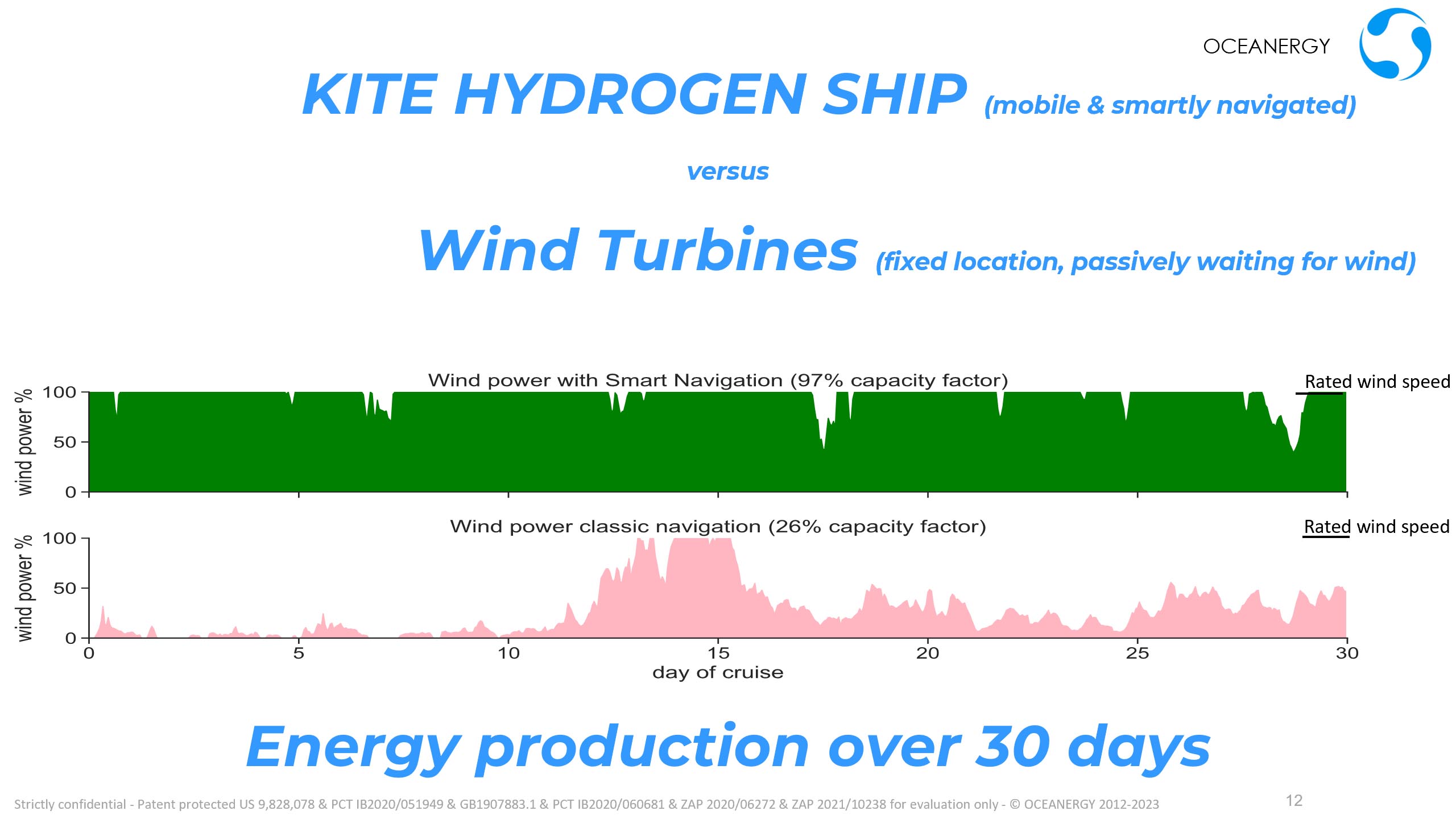

The KITE GAS/FUEL SHIP is a mobile wind power plant. An Energy Ship, specifically designed to harvest wind energy on the open ocean, far from land. It is smartly navigated, according to the wind forecast. This results in permanent and strong wind. Our simulations with previous years’ actual wind data show that they can operate 97% at the system’s rated wind speed and rated power of its generators. This is far superior to offshore wind turbines at a fixed position, which only operate at far less than 20-26% of their rated wind speed or rated power.

4x more power. The difference is evident. Mobility and SMART NAVIGATION results in 4x more energy per annum, as show in above graphic.

2x more power. Deployment far offshore, on the open ocean, at least in 2x more wind power.

4x more power. On top comes superiority of Airborne Kites from harvesting wind at altitude, adaptively, with 4x more wind power.

So in total 32x more energy harvest, per annum and per square meter.

All this with the potential to deploy a multitude of square meters with Kites, compared to swept square meters of turbines. Importantly, the translational, linear force of Kites, which are mast-less wind harvesting technologies, allows for that. As opposed to torque on the mast-foot of turbines or sails, a fact that limits their scaling.

Kites are the wind harvesting systems of the future. Their enormous scalability justifies investment in this technology, which is difficult to master, but once you succeed, it will pay off vastly.

The KITE GAS/FUEL SHIP actively navigates to areas of high wind speeds. A further advantage over fixed wind power plants is it flexibility to find the best market to sell H2 or e-fuels, and its flexibility to react to changing wind systems due to climate change.

Is is an RES (renewable energy source),

with integrated H2 conversion and storage,

and with logistics up until offload at terminals for H2 (hydrogen), NH3 (ammonia), CH4 (e-LNG), or synCrude.